The evolution of digital monitoring systems has brought a significant shift in how we assess and enhance the performance of diesel engines. These advanced technologies provide real-time insights through various gauges and tools, allowing operators to make informed decisions that can drastically improve engine efficiency and longevity. In an age where maximizing performance is paramount, understanding the nuances of these systems becomes essential.

Digital monitoring systems offer a comprehensive suite of tools designed to measure critical parameters such as fuel consumption, temperature, and pressure. By utilizing sophisticated gauges, these systems enable users to closely track their diesel engines’ operational efficiency. This data-driven approach not only assists in identifying performance issues early but also facilitates preventive maintenance, reducing downtime and costs.

Furthermore, the integration of smart technologies within these digital monitoring systems allows for more granular analysis of diesel engine performance. With the capability to collect and analyze large volumes of data, operators can pinpoint inefficiencies and optimize performance metrics more effectively than ever before. As such, leveraging these digital solutions can lead to substantial improvements in fuel economy and emissions control, aligning with the industry’s goals for sustainability while enhancing overall performance.

Selecting the Right Digital Gauges for Diesel Engines

Choosing the appropriate digital gauges is crucial for optimizing the performance of diesel engines. These tools provide real-time data on various parameters, helping to monitor engine health and efficiency effectively.

First, consider the types of gauges available. Essential instruments include turbo boost gauges, exhaust gas temperature (EGT) gauges, oil pressure gauges, and fuel pressure gauges. Each tool serves a distinct purpose and offers valuable insights that can aid in fine-tuning engine performance.

Next, evaluate the accuracy and responsiveness of the gauges. High-quality digital gauges should provide precise readings that can quickly adapt to changes in engine conditions. This responsiveness is vital for making immediate adjustments to improve performance and prevent potential mechanical failures.

Additionally, assess the ease of installation and compatibility with existing systems. Some digital gauges offer plug-and-play capabilities, while others may require more complex setups. Ensure that the selected tools are compatible with your diesel engine model to achieve optimal integration.

Furthermore, consider the durability and design of the gauges. Diesel engines operate under harsh conditions, and robust gauges can withstand vibrations, extreme temperatures, and exposure to contaminants. Choose designs with clear displays to enhance visibility during operation.

Finally, analyze the data interpretation capabilities of the gauges. Many digital gauges come equipped with software that allows for advanced data logging and analysis. This feature can be instrumental in identifying trends and making informed decisions to enhance performance and maintenance schedules.

In conclusion, selecting the right digital gauges for diesel engines involves careful consideration of functionality, accuracy, ease of installation, durability, and data capabilities. Utilizing the appropriate tools can significantly impact the efficiency and longevity of diesel engine performance.

Integrating Performance Tools with Existing Diesel Systems

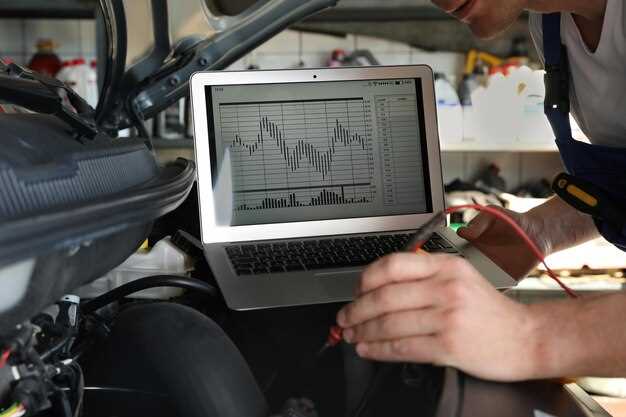

Integrating performance tools with existing diesel systems is essential for optimizing efficiency and enhancing overall engine performance. The use of digital gauges has revolutionized the way operators monitor critical parameters such as fuel consumption, engine temperature, and exhaust emissions. By leveraging these digital tools, users gain real-time insights into engine behavior, enabling them to make informed decisions to improve performance.

One of the primary advantages of integrating performance tools is the ability to diagnose issues proactively. Digital monitoring systems can detect anomalies or deviations from optimal performance standards. This capability allows for early intervention, preventing more significant problems that could lead to costly repairs or downtime. In addition, these tools often provide historical data logging, which can help identify patterns and trends over time.

When implementing digital gauges within existing diesel systems, it is crucial to ensure compatibility. Many modern performance tools are designed to interface seamlessly with various engine management systems. However, older diesel engines may require additional adapters or controllers to bridge the gap between traditional analog gauges and contemporary digital monitoring systems. This process often involves retrofitting existing components to enhance functionality without compromising the integrity of the original system.

Moreover, integrating performance tools can lead to improved fuel economy. By continuously monitoring fuel flow and engine load, operators can adjust driving habits or engine settings to optimize fuel utilization. Digital gauges provide immediate feedback, allowing for instant adjustments that positively impact operational costs and environmental footprints.

Training and education are also vital when integrating performance tools. Users need to understand how to interpret data from digital gauges effectively. Familiarity with the specific metrics displayed and their implications on overall engine performance ensures that operators can respond to issues swiftly and correctly, maximizing the benefits of the integrated tools.

In conclusion, the integration of performance tools with existing diesel systems fosters a more efficient, reliable, and sustainable operation. By utilizing digital gauges for precise monitoring and leveraging historical data for informed decision-making, operators can enhance diesel performance, reduce operational costs, and ensure compliance with environmental regulations.

Interpreting Data from Monitoring Systems for Performance Improvements

The use of digital monitoring systems has revolutionized the way we assess and enhance diesel engine performance. These tools provide a wealth of data that, when analyzed correctly, can lead to significant performance improvements.

Firstly, engine parameters such as fuel consumption, exhaust temperature, and engine speed are continuously monitored and recorded. Analyzing this data allows operators to identify patterns and anomalies that may indicate inefficiencies. For instance, if fuel consumption spikes without a corresponding increase in output, it may signal issues in the fuel injection system or turbocharging.

Furthermore, advanced detection algorithms enable real-time diagnostics. By applying machine learning techniques to historical performance data, these systems can predict potential failures or maintenance needs before they lead to downtime. This proactive approach not only enhances performance but also extends the engine’s operational lifespan.

Another critical aspect is the importance of benchmarking performance data against industry standards. Understanding how your diesel engine performs compared to similar models can highlight specific areas that require optimization. For example, if your engine’s emissions exceed regulatory limits, targeted adjustments can be made to the combustion process, thereby improving overall efficiency.

Visualization tools integrated within monitoring systems also play a crucial role. Dashboards that present data in an intuitive format help operators quickly grasp performance metrics. By focusing on KPIs such as fuel efficiency or power output, teams can make data-driven decisions, optimizing maintenance schedules, and operational strategies.

In conclusion, effectively interpreting data from digital monitoring systems is essential for achieving optimal diesel performance. By leveraging advanced analytics and visualization tools, operators can identify inefficiencies, predict maintenance needs, and implement necessary adjustments. This not only maximizes performance but also ensures compliance with environmental regulations, underscoring the importance of data-driven decision-making in modern diesel engine management.